Daily Quizzes

Mock Tests

No tests attempted yet.

Select Category

The Union Cabinet of India has given its nod to the "Scheme to Promote Manufacturing of Sintered Rare Earth Permanent Magnets" that comes with a financial outlay of ₹7,280 crore. The plan is to create a domestic manufacturing capacity of 6,000 metric tonnes per annum (MTPA) of rare-earth permanent magnets (REPM) in India through the fully integrated plants covering the whole process from rare-earth oxide processing to the production of the final magnet. The revolution essential to sectors such as electric vehicles, renewable energy, electronics, aerospace, and defence is the first target. It intends to cut down the import dependence and make the supply chain more robust for strategic and high-technology industries. Besides, the scheme is in line with the larger national objectives of self-reliance and clean technology transition.

Rare Earth Permanent Magnets Explained in Simple Terms

-

Rare Earth Permanent Magnets (REPMs) are the most powerful kinds of permanent magnets that are made from alloys of rare-earth elements.

-

Firstly, they offer exceptional magnetic strength, high energy density, and long service life.

-

REPMs are the major components of electric vehicles, renewable energy systems, electronics, aerospace, and defence equipment.

-

Without any external power, these magnets can still hold a strong magnetism, which is the main reason why they are used in highly efficient motors and generators.

-

Besides, their small size and magnetic stability qualify them as the most indispensable components in advanced technologies that have strong and stable magnetic fields as a prerequisite.

-

REPMs are the main pillars of modern innovations that lead to cleaner energy and next-generation industries.

Conclusion

It's a significant move for India in terms of tech-independence and sophisticated industrial growth with its ₹7,280 crore program to develop rare earth magnet manufacturing. The plan, which revives local production capacity, lessens the country's reliance on imports and is instrumental in the development of sectors that are vital to the economy, such as the ones mentioned above i.e., EVs, renewable energy and defence. With this step, India is placed to be a globally competitive destination for the production and innovation of high-performance magnets.

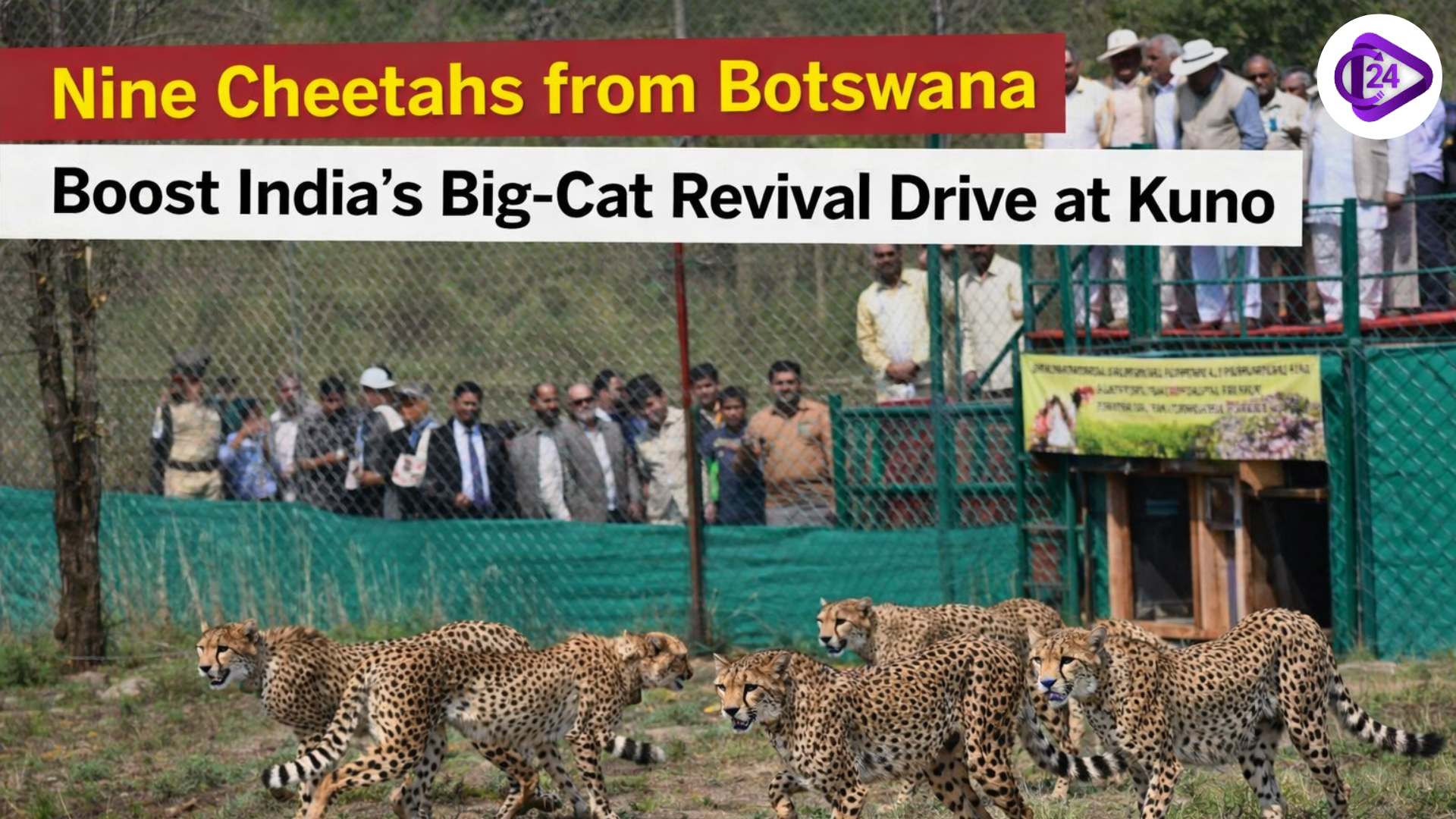

Nine Cheetahs from Botswana Boost India’s Big-Cat Revival Drive at Kuno

Nine Cheetahs from Botswana Boost India’s Big-Cat Revival Drive at Kuno Raksha Rajya Mantri Opens Chungthang-Lachen Road & Taram Chu Bridge

Raksha Rajya Mantri Opens Chungthang-Lachen Road & Taram Chu Bridge Jammu University Hosts Goonj 2026 Youth Festival

Jammu University Hosts Goonj 2026 Youth Festival North East Spring Festival 2026: Exciting 3-Day Event Begins at NEZCC Complex, Dimapur

North East Spring Festival 2026: Exciting 3-Day Event Begins at NEZCC Complex, Dimapur International Energy Agency (IEA): Structure, Functions & India’s Membership Bid

International Energy Agency (IEA): Structure, Functions & India’s Membership Bid Rajasthan Launches Homestay Scheme 2026: Eligibility, Subsidy Benefits

Rajasthan Launches Homestay Scheme 2026: Eligibility, Subsidy Benefits Goa Hosts World Ocean Science Congress 2026

Goa Hosts World Ocean Science Congress 2026 Vasai Cathedral Wins UNESCO Heritage Award 2025

Vasai Cathedral Wins UNESCO Heritage Award 2025 Vanjeevi Didi Scheme at Palamu Tiger Reserve

Vanjeevi Didi Scheme at Palamu Tiger Reserve Bharat VISTAAR

Bharat VISTAAR