Indian researchers have developed an eco-friendly and energy-efficient method to produce hydrogen peroxide (H₂O₂) using sunlight. This innovative approach utilizes Covalent Organic Frameworks (COFs) as photocatalysts, enabling sustainable production without harmful by-products. The new method significantly reduces energy costs and enhances industrial efficiency. With applications in disinfection, paper bleaching, and chemical synthesis, this breakthrough could revolutionize multiple industries. The research marks a major step toward greener and more sustainable chemical manufacturing.

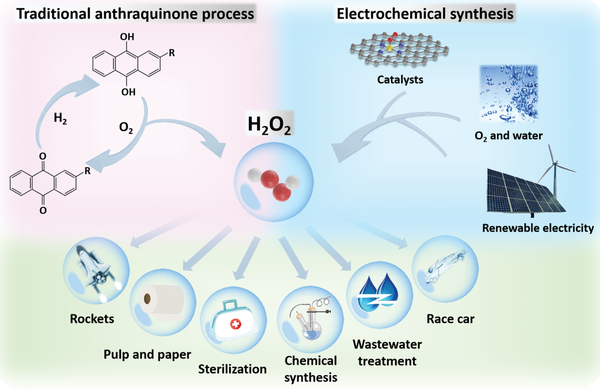

Research teams have developed an energy-saving sustainable approach to manufacture hydrogen peroxide (H₂O₂) which serves as a fundamental chemical throughout various industries such as disinfection together with paper bleaching and chemical synthesis.

Key Highlights of the Research:

Significance of Hydrogen Peroxide (H₂O₂):

-

The synthetic product serves environmental disinfection needs and supports chemical synthesis as well as paper bleaching and fuel cell operations.

-

Economic interest in hydrogen peroxide continues to grow owing to public health concerns about disinfection and the escalating surgical procedures alongside hospital infections.

Limitations of Existing Industrial Methods:

-

Industrial manufacturing of H₂O₂ through anthraquinone oxidation produces more than 95% of the entire H₂O₂ created globally.

-

Hydrogen Peroxide production requires excessive energy at high expense which leads to dangerous by-products.

New Eco-Friendly Approach:

-

Scientists work to create financially viable sustainable systems that use renewable resources.

-

The recent emergence of Covalent Organic Frameworks (COFs) as photocatalysts brings potential because of three important features.

-

Modifiable catalytic sites.

-

Efficient light-harvesting in the visible range.

-

Good water affinity.

-

Research team at S. N. Bose National Centre for Basic Sciences in Kolkata:

-

Scientists designed hydrazone-linked COFs which demonstrated improved water reacting properties.

-

These COFs promote key reactions:

-

Water Oxidation Reaction (WOR).

-

Oxygen Reduction Reaction (ORR).

-

The photocatalytic system effectively produced H₂O₂ through sunlight activation.

-

Key Achievements:

-

H₂O₂ production quantities exceeding 550 μmol g⁻¹ h⁻¹ were achieved by this photocatalyst under sunlight illumination which surpassed most organic photocatalysts.

-

The combination of water-benzyl alcohol solution at 90:10 produced H₂O₂ production of 21,641 μmol g⁻¹ h⁻¹.

-

The material shows readiness to be used in continuous flow reactors which can enhance industrial production capabilities.

Conclusion:

-

The renewable H₂O₂ synthesis method holds promise as an environmentally friendly method for industrial production.

-

This development enables the transfer of lab-based technologies into industrial operation which yields advantages across different business sectors.

-

The method has potential to develop a sustainable H₂O₂ production system which decreases environmental impact in comparison to existing H₂O₂ manufacturing processes.

World’s 1st Functioning AI-designed Viral Genome

World’s 1st Functioning AI-designed Viral Genome AI-led Efficiencies Could Contribute to 8% GDP Growth Target: NITI Aayog

AI-led Efficiencies Could Contribute to 8% GDP Growth Target: NITI Aayog India Projects Five-fold Growth in Space Economy to $44 Billion by 2033

India Projects Five-fold Growth in Space Economy to $44 Billion by 2033 Ministry of Tribal Affairs to Launch the Beta Version of “Adi Vaani”

Ministry of Tribal Affairs to Launch the Beta Version of “Adi Vaani” UNGA Launches Two New Initiatives to Strengthen Global Cooperation on AI Governance

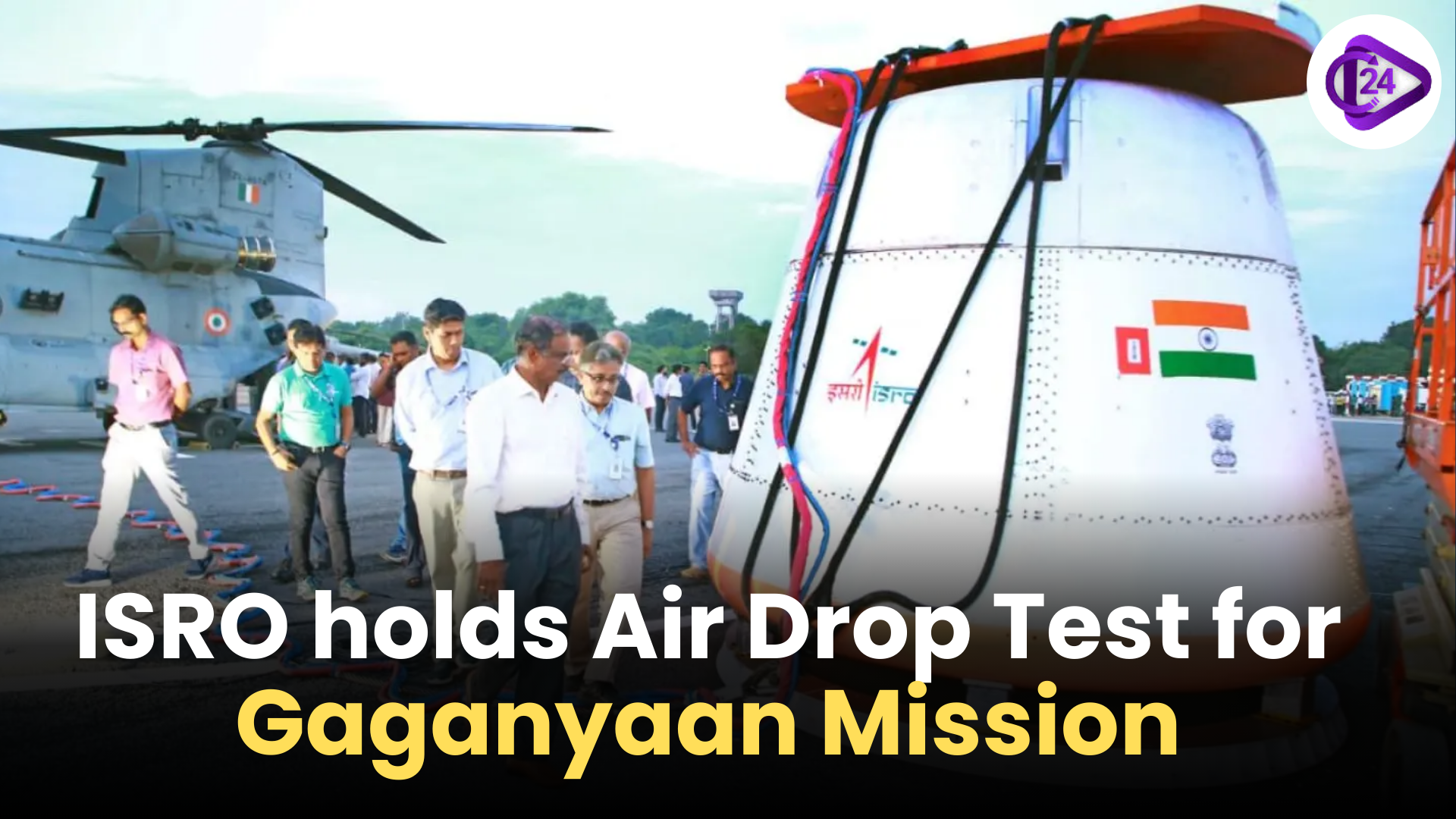

UNGA Launches Two New Initiatives to Strengthen Global Cooperation on AI Governance ISRO holds Air Drop Test for Gaganyaan Mission

ISRO holds Air Drop Test for Gaganyaan Mission Tiny Gold Particles can help early detection of Parkinson’s Disease

Tiny Gold Particles can help early detection of Parkinson’s Disease National Space Day 2025 Celebrated Across India

National Space Day 2025 Celebrated Across India Malaria’s New Frontlines: Vaccines, Innovation, and the Indian Endgame

Malaria’s New Frontlines: Vaccines, Innovation, and the Indian Endgame India-NASA Earth Observation Partnership: NISAR Satellite Launch

India-NASA Earth Observation Partnership: NISAR Satellite Launch